• Easy mounting, ball & socket hanging system, specially designed for vaulted ceiling up to 45° also available.

• High quality and lasting of plating & painting finish. Salt spray test for Anit-Rust assurance.

• Wide selection of blade, with reversible motor rotation option, color & finishing.

• Pull chain or remote control of speed, forward & reverse switch for all seasons air movement.

• Light adaptable, wide variety of light kits and shade.

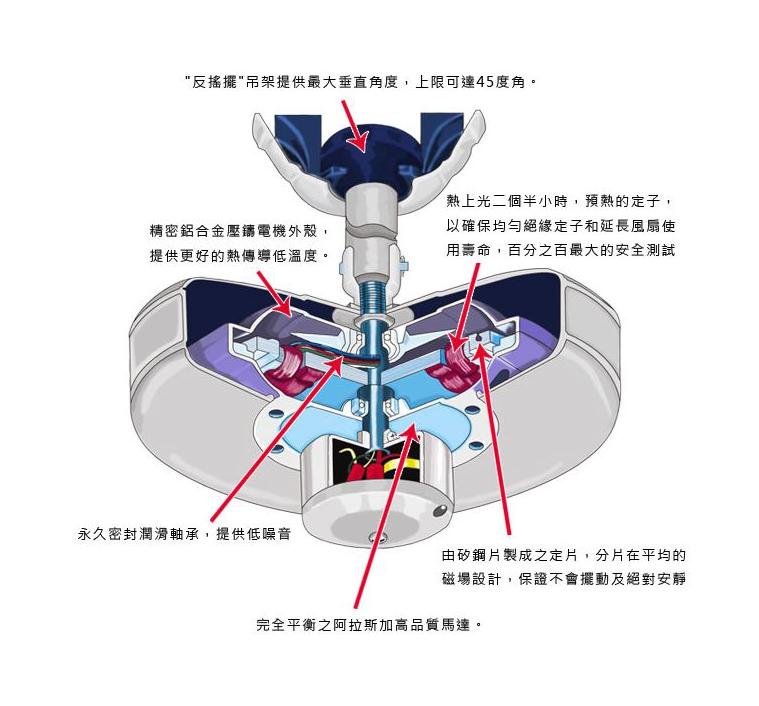

• "Anti-wobble" hanger assembly provides max.verticality at any ceiling up to a 45° incline angle.

• Precision aluminum die-casting motor case provides better thermal conduction resulted lower temperature and long life-span.

• Hot-dip varnishing process for 2-1/2 hours, pre-heats the stator to ensure easy penetration and evenly insulated the stator thus prolong fan motor life.

• 100% high voltage puncture test for max. safety.

• Stator made by silicon steel. Lamination designed by even magnetic field to ensure no wobbing and quiet rotation.

• Permanent sealed and lubricated bearings provide noiseless & longer life,maintenance free operation.