3. Mounting bracket opening should be less than 0.5mm expand.

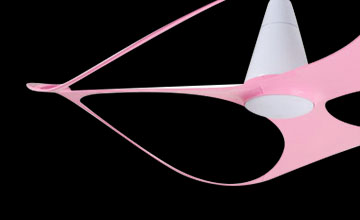

1. The blade holder should have no cracks and damage determining by visual inspection with 4X magnifying glass.

2. Make metal fatigue test to find out the weak point of blade holder which may not be found from Static loading test.

| VENTO | OTHER FACTORIES | |

| Motor Core Size | 188 series& 212x 25m/m | 153 x 15m/m |

| Motor Housing Material | The motor casing is stamped from aluminum, which has the advantages of fast heat dissipation and low temperature rise. | The motor casing is stamped from iron sheets, which has slower heat dissipation, higher temperature rise and higher power consumption. |

| Motor Casing Processing | Accurate processing of the surface of the Palin hole and rotor with a high-precision CNC machine, 100% balance check, precision balance and computerized tolerance adjustment for ultra-quiet operation, enabling Palin to continue to operate for a long time, the motor is used at a lower temperature for long lasting life. | Stamping processing, poor precision and balance, may cause defects when the motor starts. |

| Steel Sheet | Cut into narrow grooves with high-quality silicon steel sheet, the magnetic range is consistent and the magnetic flow can flow smoothly. The flux and surface heat dissipation are better than other brands of motors, and the efficiency is 10% higher than other brand motors. | The width of the silicon steel sheet groove is wider than VENTO, which results in lower flux density and surface heat dissipation than VENTO. |

| Steel Sheet | Cut into narrow grooves with high-quality silicon steel sheet, the magnetic range is consistent and the magnetic flow can flow smoothly. The flux and surface heat dissipation are better than other brands of motors, and the efficiency is 10% higher than other brand motors. | The width of the silicon steel sheet groove is wider than VENTO, which results in lower flux density and surface heat dissipation than VENTO. |

| Motor Winding | Fully automatic winding and hot water treatment, 1800 to 2100 feet of winding, the motor can run at a lower temperature , safer and extend the life of the motor. The copper wire used is from reputable manufacturers such as PEWC - high cost, better quality and more stable. | The use of lower quality and cheaper copper wire, 1500 feet of winding, is not stable. |

| Motor Stator | The tolerance of the quasi-linear line is 0.1 m/m and the tolerance of the quasi-circle is 0.03 m/m. This high precision requirement is for better motor operation. | a lower precision rotor. |

| Insulating Processing | Automatic preheating and drying through the machine allows the varnish to completely condense, requiring at least 3 hours per process to allow the varnish to absorb evenly and provide better insulation. | Using a fan under the sun, hand-condensed and dried varnished water makes it unevenly distributed and poorly insulated. |